Research Counseling

Research at IAM, RWTH Aachen University

Our principal research interest is to study the hierarchically structured biomaterials, e. g., spider silk and nacre, as well as new advanced materials, such as silica aerogel, aerographene, cellulose aerogel and their composites, by using computational methods. This approach starts from an atomistic level, where structures and properties of each constituent or building block are studied under loading and at failure. It creates a link between the understanding of the mechanical behavior of materials at the nanoscale, and its macroscopic mechanical features.

Our research work mainly utilizes classical molecular dynamics (at nano-scale level) and finite element method (at macro-scale level) techniques.

A novel combined method for highly brittle materials such as aragonite crystals is proposed, which provides an efficient and accurate in-sight understanding for multi-scale fracture modeling. In particular, physically-motivated molecular dynamics (MD) simulations are performed for crack modeling on the nano-scale, whereas a macroscopic modeling of fracture has proven successful using the diffusive phase-field modeling (PFM) technique. The proposed computational approach, that encompasses mechanics on discrete and continuum levels, can assist multi-scale modeling and easing, for instance, the simulation of biological materials and the design of new materials.

Spider dragline silk has the unusual combination of high strength, extensibility and toughness, which outperforms some of the best man-made materials in terms of its mechanical performance. Dragline silk has a semi-crystalline structure consisting of crystalline region of short polyalanine segments that form stiff β-sheet nano-crystals surrounded by amorphous glycine-rich domains, which provides extensibility of the fiber. A three dimensional finite element model of silk fiber is proposed, which is based on the secondary structure of the Araneus diadematus silk fiber, which takes into account the plasticity of β-sheet crystals as well as the viscous behavior of the amorphous matrix. The silk fiber model shows the predicted mechanical properties are in excellent agreement with available experimental evidence. The proposed continuum mechanics based macro-scopic silk fiber model, not requiring any empirical parameters, and contribute towards an improved understanding of silk fiber mechanics during deformation and the source of the toughness of this extraordinary fiber. Hence, it is an efficient model for the design of artificial silk fiber as well as applicable to other composite materials.

Nacre, also known as the Mother of Pearl is an organic-inorganic composite material produced by some mollusks as an inner shell layer. In the last three decades, the structure and the toughening mechanism of nacre have been the subject of intensive research. This interest originates from nacre’s excellent combination of strength, stiffness and toughness. It is composed of hexagonal platelets of aragonite arranged in a continuous parallel lamina. The layers are separated by sheets of organic matrix composed of elastic biopolymers. This mixture of brittle platelets and the thin layers of elastic biopolymers make the material strong and resilient.

Aerogels are nanostructured, highly porous solids, which have, compared to other soft materials, special mechanical properties, such as extremely low densities. In this project, the mechanical properties of silica aerogel, aerographene, cellulose aerogel and their composites have been studied with molecular dynamics (MD) simulations. The mechanical properties of the aerogel MD models in uniaxial tension and compression were studied. Moreover, cyclic loading simulations, under compression, were carried out on the models of the different densities. Under larger strains, nearly no recovery of the collapsed structural network was observed. The response is characterised by inelastic phenomena like residual deformation, hysteresis, and Mullins effect.

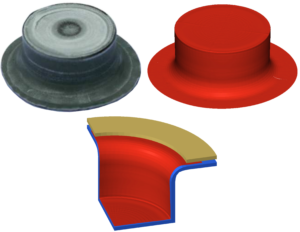

This research topic focuses on the gas detonation forming technique, which has the potential to form complex geometries, including sharp angles and undercuts, in a very short process time. Currently, finite element method simulations of the cup forming process are performed. The simulations on 3D computational models are carried out with the explicit dynamic analysis using the Johnson-Cook material model. The results obtained in the simulations are in good agreement with the experimental observations, e. g., deformed shape and thickness distribution. Moreover, the proposed computational model is capable of predicting the damage initiation and evolution correctly, which is mainly due to the high-pressure magnitude or an initial offset of the workpiece in the experiments.

Molecular dynamics simulations were carried out to investigate the temperature distribution as well as the fundamental friction characteristics such as the coefficient of friction and wear in a disc-pad braking system. A wide range of constant velocity loadings was applied on metallic brake pads made of aluminium, copper and iron with different rotating speeds of a diamond-like carbon brake disc. The quantitative description of the volume lost from the brake pads was investigated, and it was found that the volume lost increases linearly with the sliding distance. Our results show that Archard’s linear wear law is not applicable to a wide range of normal loads, e. g., in cases of low normal load where the wear rate was increased considerably and in cases of high load where there was a possibility of severe wear. In this work, a new formula for the brake pad wear in a disc brake assembly is proposed, which displays a power law relationship between the lost volume of the metallic brake pads per unit sliding distance and the applied normal load with an exponent of 0.62. This work provides new insights into the fundamental understanding of the wear mechanism at the nano-scale leading to a new bottom-up wear law for metallic brake pads.

Bachelor/Master/Ph.D. thesis at RWTH

Blending experience with the novel ideas from the young aspirants

Removing the gaps from theoretical understanding and practical world scenarios using experimental techniques

Convert your thesis work into a peer-reviewed publication

Build your professional network

Develop and improve your scientific writing

Make your thesis as an essential footstep to your professional career path

Industry sponsored Ph.D. at RWTH

Structured programs for industry sponsored doctoral theses

Long term benefits of the collaborative work for academia and industry

Establish a bridge between your industry and the institutes from RWTH Aachen University

Cultivating research culture at your organization

Collaborations with academia for technologies and businesses of tomorrow’s world

International Journal Publications

Find peer-reviewed journal publications on the following links: IAM list of publications